An Exergy workshop – A Sustainable Transition: From a Linear to Circular Economy

October 18, 2019 by Katie Jones

At Warwick University, On October 9th, 2019, Exergy hosted a 3-hour afternoon workshop titled, ‘A Sustainable Transition: From a Linear to Circular Economy’.

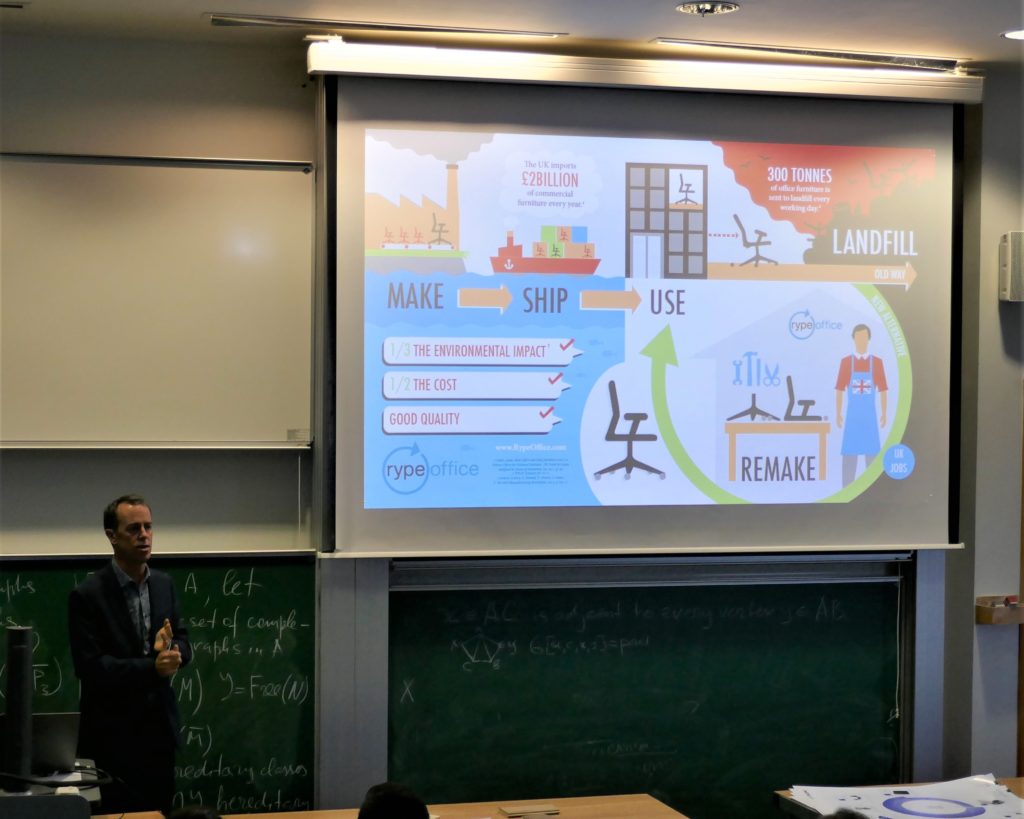

By gathering circular economy innovators and pioneers, the aim of the event was to encourage sustainable attitudes amongst consumers and current initiatives that promote circular business models within the UK. The event proved to be very successful, with around 60 people in attendance. A total of 8 speakers (Oakdene Hollins, Microcab, Chip[S]board, Recono.me, Aldstone, Rype, Circular Economy Research Network, and Exergy) discussed the ways in which they have refined and implemented the concept of circular economy. These entrepreneurs and circular economy experts demonstrated their way of revolutionizing the traditional linear, unsustainable economic model within the UK.

Rethinking the current economy model

A key theme throughout the event was the increasing popularity and public acceptance of circular economy products and processes. For example, student-formed Chip[S]board presented their creative method of turning potato waste into a viable alternative to plastic and discussed growing product interest, particularly from the fashion industry. Following speakers then discussed topics surrounding the re-design of offices to reduce furniture waste, remodeling of electronics business models and the opportunity for zero-emission transport through an innovative hydrogen vehicle. Fernando Centeno, of Exergy, discussed our innovative approach to circular engineering, including the successful AgriMax project: A Horizon 2020 success story demonstrating the commercial feasibility of extracting high value compounds from agricultural waste. Additionally, using our Aiana Verde project as an example, Exergy demonstrated the need for (and practicalities of) embedding circularity into all aspects of everyday life.

The presentations provided an exciting glimpse into the possible future of circular economy within UK business, yet underlined challenges surrounding the scale-up of technologies, maintaining cost-effectiveness and technology integration into common consumer behaviour. Despite this, discussions were incredibly positive and highlighted the need for consistent collaboration amongst circular innovators. The audience had the opportunity to gain inspiration through sharing their own ideas, businesses and technical challenges – both during the presentations and in the post-event networking opportunity.

Exergy would like to thank all partners involved for an all-round successful event – for sharing their passion and motivation and for making this initiative possible. Collaborative events are vital in the drive towards the revitilisation of current, linear business models within the UK.